Arrow Hammer Upgrades

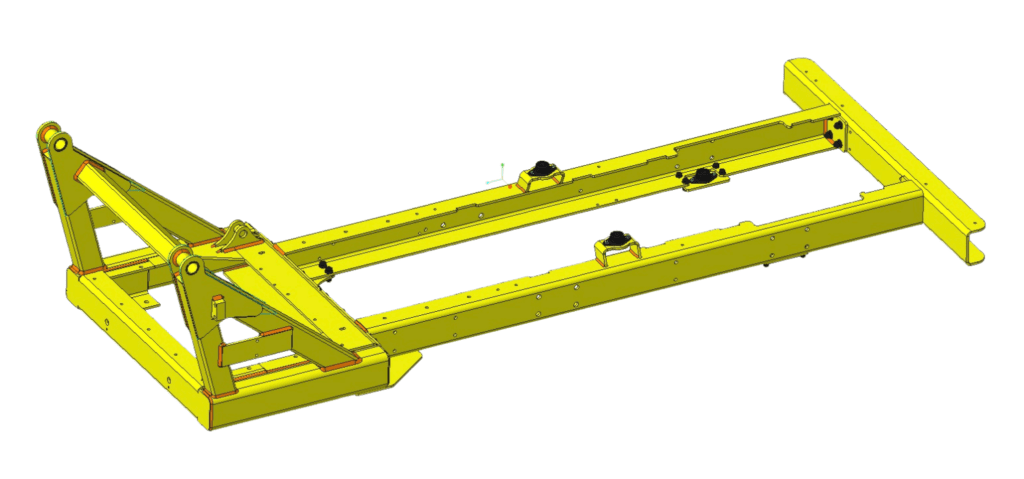

We kept all the effective parts of an Arrow Hammer and brought all the rest up to date. Being a purpose-built machine we started with a brand new frame made from high-strength steel with a bolt-together design which helps with the vibration and stress that this machine endures. We used 5/8 grade 9 flange head bolts and nuts engineered many times over!!

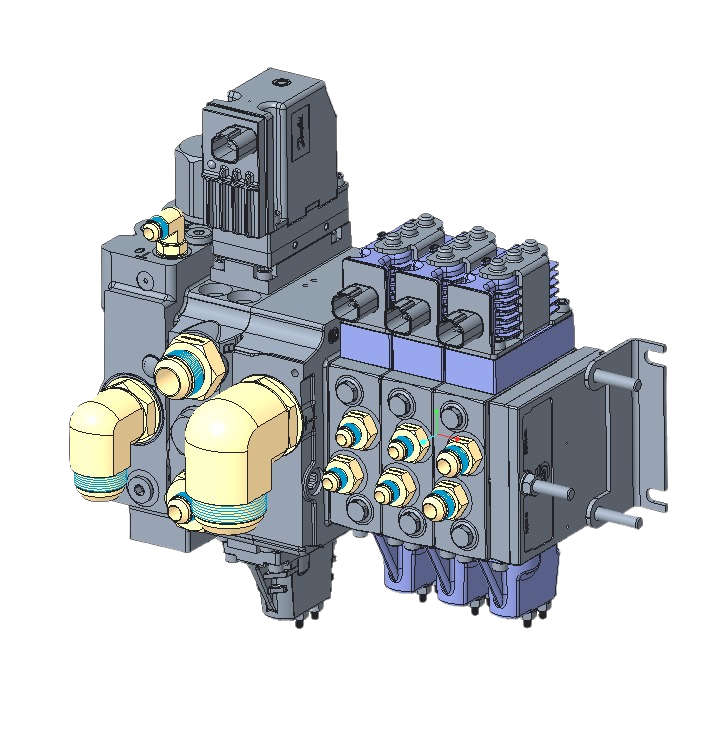

New Hammer Valve

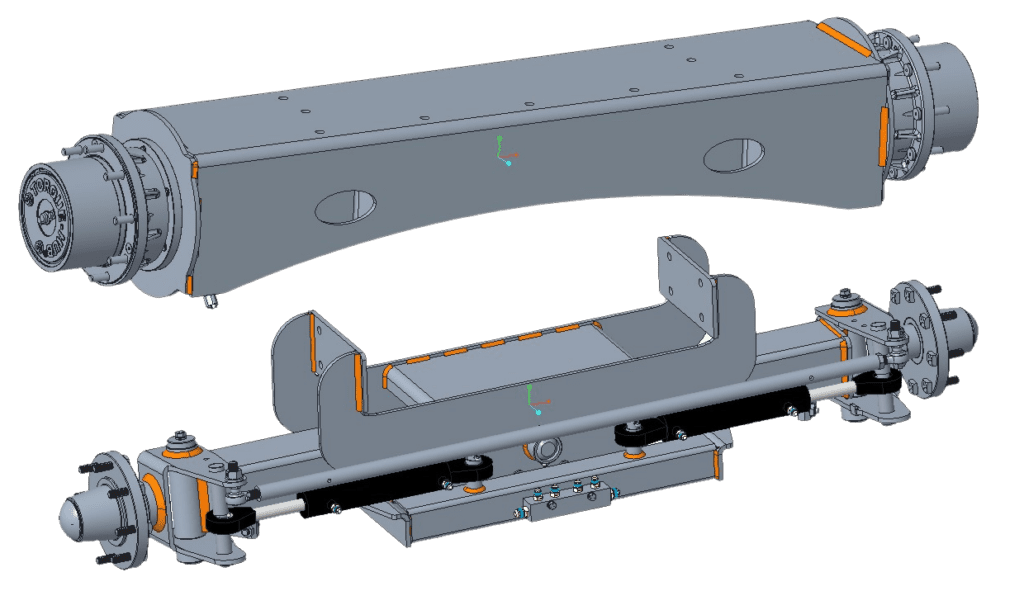

Axles

We upgraded to a modern PPG sectional valve to run all of our components. It is custom-designed with weeks of trial and testing. Every circuit is custom-designed for flow and pressures per our needs. This valve is run electronically with the ability to run it manually if required. We relocated the valve from our previous models to the side of the machine for easy service or cleaning. We protected it with a 10 gauge steel cover that can easily be removed with two rubber straps.

Lift cylinder

The lift cylinder was reigned to match our new valve and pumps. We went with a smaller bore and a bigger rod. This will make a tougher cylinder with keeping our cycle times the same or better than our previous model. We let the block and tackle self-center itself and encased the cylinder with guards. We put hand turn knobs on all the guards so if you need to change a cable you do not need a wrench to remove the guards.

New Engine and Drive Train

With emissions being important we went with a Cummins turbo diesel. It meets all the new emissions requirements and is very fuel-efficient. We coupled this engine with a Hydrostat transmission and a double pump. All are designed and engineered to work together. A forward and reverse pedal is all you need with our 3 modes of travel via push button.

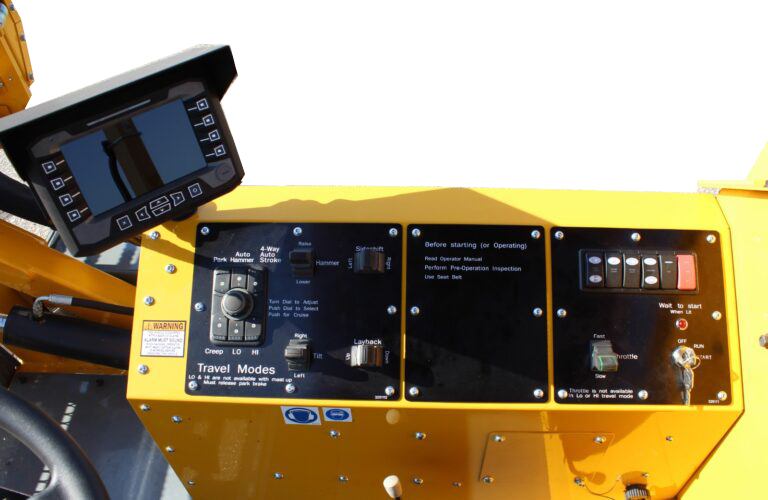

Operators Station

This was a big change, we moved the operator ahead 8 inches and moved all the controls to the right side. We added a swivel suspension seat, tilt steering wheel, and forward and reverse pedals. This allowed the operator to look beyond their feet to see what they are hammering and how the progress is going. We added a 7” “user interface” screen. This has all your gauges and information. It is also where the settings of the machine are controlled.

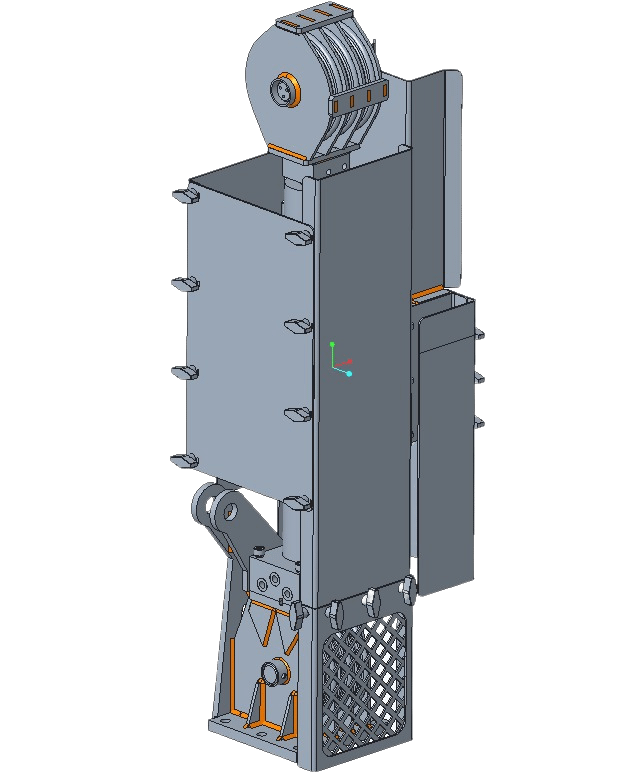

Hose and Cable Track System

This is a custom-made track system with a worldwide resume, hundreds of thousands of cycles are nothing for this system. We designed it to hold all of our hoses up and out of the way for a clear operator’s view. It folds up nicely when storing the mast.

7” Display (User Interface)

This display comes with a sun visor and is Ip67 rated. This is where an operator monitors gauges, service intervals, fault codes and more. Pages include “Home” (instrument cluster) “Auto cycle” “calibration” “Fault” “Engine” “Production” and Trac lock feature. The user interface is push button operated for reliability, and ease of use even with gloves on. The display can be removed for long time storage or seasonal use.

Get in Touch

Email Us: paul@packerbrothers.com

Visit Us: 850 Hwy 55, Brooten, MN 56316, USA