Direct Drive Trowel

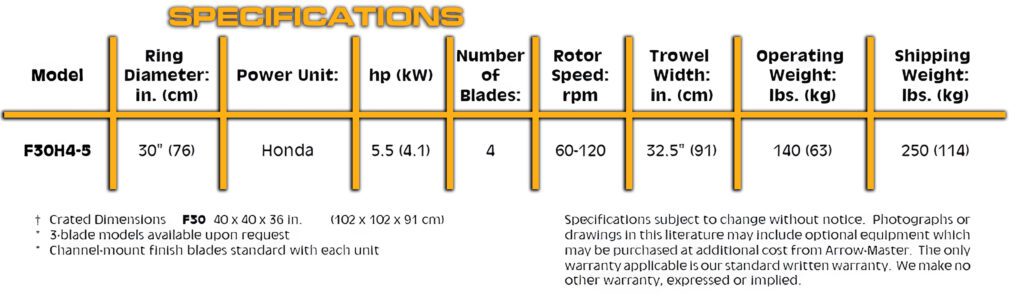

Model F30: Features & Benefits of Direct-Drive Trowel

- Low Center of Gravity: Ensures stability during operation.

- No Belt Adjustments: Simplifies maintenance and increases efficiency.

- Reduced Wobble & Side Torque: Provides smoother performance.

- Increased Power to Gearbox & Spider: Enhances productivity and precision.

- Extended Blade Life: Built for longevity and cost-effectiveness.

- Unique Direct-Drive System: The only trowel in the industry with this feature.

- Enclosed Blade-Pitch Mechanism: Protects critical components.

- Electric Deadman Switch: Prioritizes operator safety.

- Heavy-Duty Gearbox: Ensures long-term durability and performance.

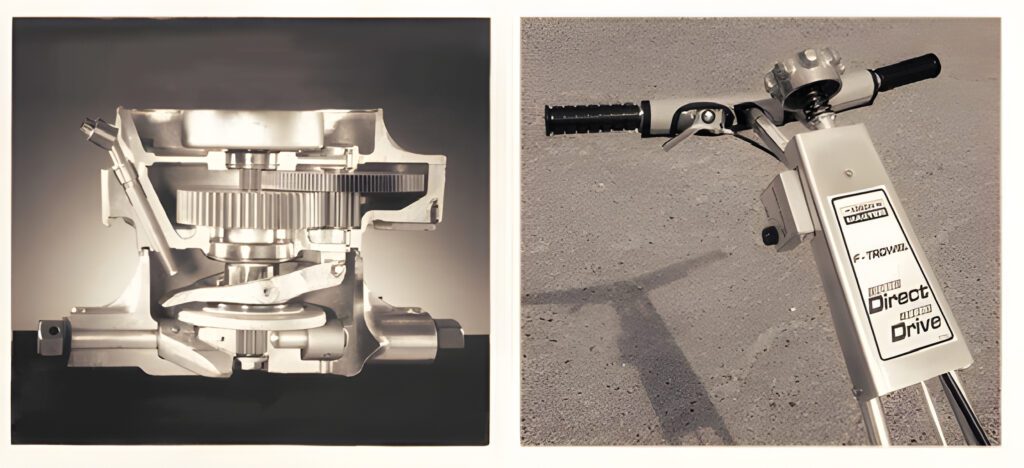

What Direct-Drive Means for the Professional Finisher

Conventional Belt Drive vs. Direct Drive:

A conventional belt drive has a high center of gravity, leading to unbalanced power transfer from the engine to the gearbox. This creates wobble, reduces power efficiency, and makes achieving a smooth finish more difficult. In contrast, a direct-drive trowel offers a low center of gravity and balanced power transfer, resulting in smoother, flatter finishes with easier handling. The direct-drive system minimizes power loss and enhances control for professional-grade results.

The enclosed spider assembly prevents concrete buildup around the gearbox and pitch control, ensuring smooth operation and minimal maintenance. Additionally, the electric deadman switch enhances operator safety by automatically shutting down the machine if control is lost, providing security during operation.

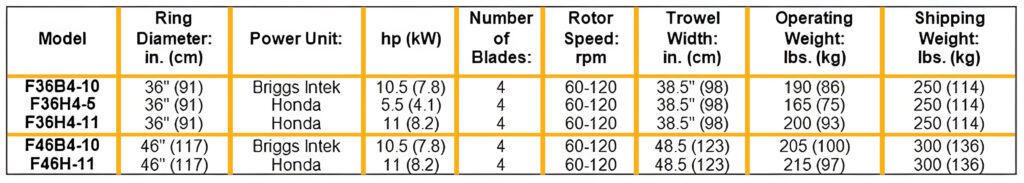

Model F36 and F46

The Arrow Master models F36 and F46 offer professional-grade concrete finishing solutions with advanced direct-drive technology. These models feature a low center of gravity for enhanced stability, reduced wobble, and increased power transfer to ensure smoother, flatter finishes. Both models come with easily replaceable blade clips, a stabilizer ring for optimal blade balance, and an electric deadman switch for operator safety. The F36 and F46 are built for durability and precision, making them ideal for demanding construction projects.

Features and Benefits

- The enclosed spider assembly prevents concrete buildup around the gearbox and pitch control, ensuring smooth, uninterrupted operation.

- Blade replacement clips are easily removed, allowing for quick maintenance and fast channel mount blade changes.

- The stabilizer ring prevents blade flex, maintaining balance for a smoother, flatter finish.

- An electric deadman switch enhances operator safety, providing automatic shutdown in case of control loss.

Get in Touch

Email Us: paul@packerbrothers.com

Visit Us: 850 Hwy 55, Brooten, MN 56316, USA